We recently chatted with Michael Kanoza, a product graphics analyst in the special visual collaboration department (how’s that for a job title!) about how Steelcase stays ahead of workplace trends to create spaces that help people work, learn, and heal.

Steelcase was established in 1912. Their first patent was for a metal wastebasket; replacing wicker with steel was a lifesaving innovation at that time in crowded cities where fires spread quickly.

Since then, the company established roots as a top office furniture manufacturer. Though, they aren’t just any furniture manufacturer. Steelcase differentiates itself with its deep knowledge in the commercial interiors industry as well as its special visual collaboration department. This department helps communicate bespoke products before they are manufactured.

Over the years, Steelcase has been at the forefront in commercial interiors transformation. Between the digital transformation and changing regulatory requirements, Kanoza has seen the industry grow and transform.

These changes have driven product design as well as the way Steelcase works with its clients. Instead of only manufacturing one-size-fits-all workplace furniture, they’ve had to adapt to custom requirements and consultation needs. In the office furniture business, there has always been a need to produce what’s known as a ‘special’. Producing ideas and communicating them in a quick, visual format for space planning software is key.

Trends, trends, and more trends

The work environment is more complicated than it has ever been before. People are working longer hours and in recent years have seen the rise of remote working. Some employees benefit from being in the office (second place) while others prefer to work from home (first place) or from a coffee shop (third place). So, what exactly are first, second, and third places? According to sociologist Ray Oldenburg, working from a home environment is considered a “first place”, while working from a cafe or coffee shop is considered a “third place”, and the office is a “second place”.

These “places” – especially “third places” are starting to define the modern workplace, which has leading organizations jumping to remodel their definition of a workplace. With factors such as increasing business demands, longer working hours, and more remote employees to consider, companies are trying to find ways to help increase employee comfort, efficiency, and innovation.

So, what attracts employees to “third places”?

“The ability to work without colleagues stopping by, lounge furniture with a home-like feel, the energizing buzz of people, access to good food, an attractive ambiance,” said Frank Graziano, manager of advanced applications at Steelcase. “Third places—essentially, public places that help people get through the day or allow them to gather—have been inspiring innovation and stirring conversations throughout Western civilization.”

Employers who realize the importance of third places try to capture its essence by creating spaces within the workplace that re-energize teams and promote creativity and innovation. An example of this trend in action is Google’s new coffee shop that it opened on its California campus.

“We’re bringing the comforts of home and community of third place to the workplace to make the office the best place to work,” said Graziano. “When you do that, it changes the physical character and social experience of the workplace. It fosters a shift in work culture.”

Connecting design to customer values

Not only are there trends within the workplace for employees and employers, but there are also significant industry niches that have spurred from this movement: custom workplace furniture design.

“We are seeing a huge need to accommodate co-creation between the customer, dealer designer, and my department which handles special furniture for Steelcase,” says Kanoza. “It’s important for all stakeholders to be on the same page and designing for the same goal: the betterment of the workplace.”

Inherent within this is sustainability. In today’s conscious consumer climate, the care and rigor of manufacturing processes can be a major deal-breaker. That is why designers such as Steelcase take this very seriously and design specifically with sustainability in mind.

“We believe that providing the best solutions for our customers begins by ensuring they’re the best solutions for our environment. That’s why every step of the way – through design, manufacturing, delivery, and product lifecycle – we consider the impact of our work on people and on the environment and uncover opportunities to make things better,” says Graziano.

Taking it further, they also consult with individual clients to ensure their proposals meet each firm’s sustainability goals.

The front lines of workplace transformation

Across the board, customers are requiring creative and cost-effective solutions to their special office furniture needs. The team at Steelcase conducts hours of research into office work behavior and trends in order to keep up with customer-driven demand. Afterward, the team determines if the design is even possible to manufacture.

“We research the feasibility, viability, and cost for a special product and communicate it using our special visual communication process,” says Kanoza.

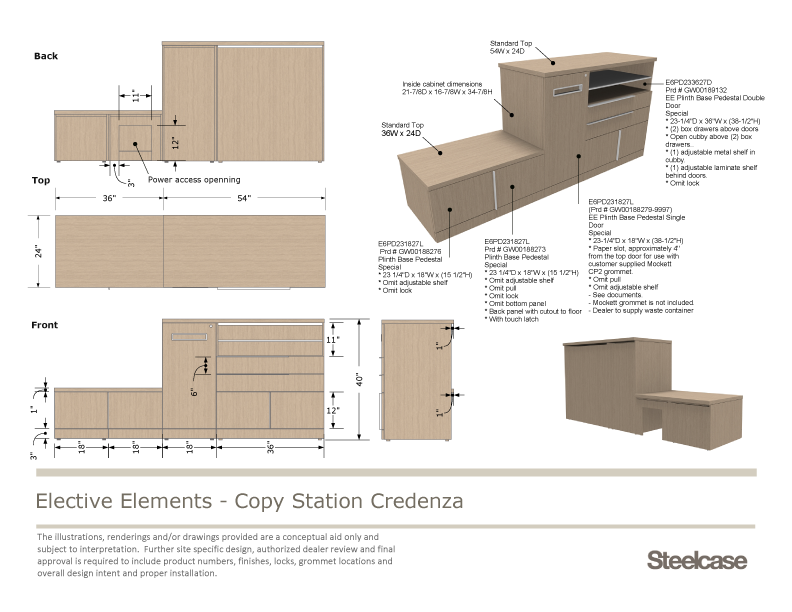

Customers who require custom products expect to see what it might look like before they commit to a purchase. In response, Steelcase’s dealership designers have to showcase their proposed products within floor plans using renderings and space planning software.

Using technology to innovate

On top of being at the forefront of design innovation and workplace trends, Steelcase also utilizes technology to drive these initiatives forward.

They were the first manufacturers to be listed on the world’s largest 3D model library, 3D Warehouse, and are now one of the largest producers of 3D models on the platform.

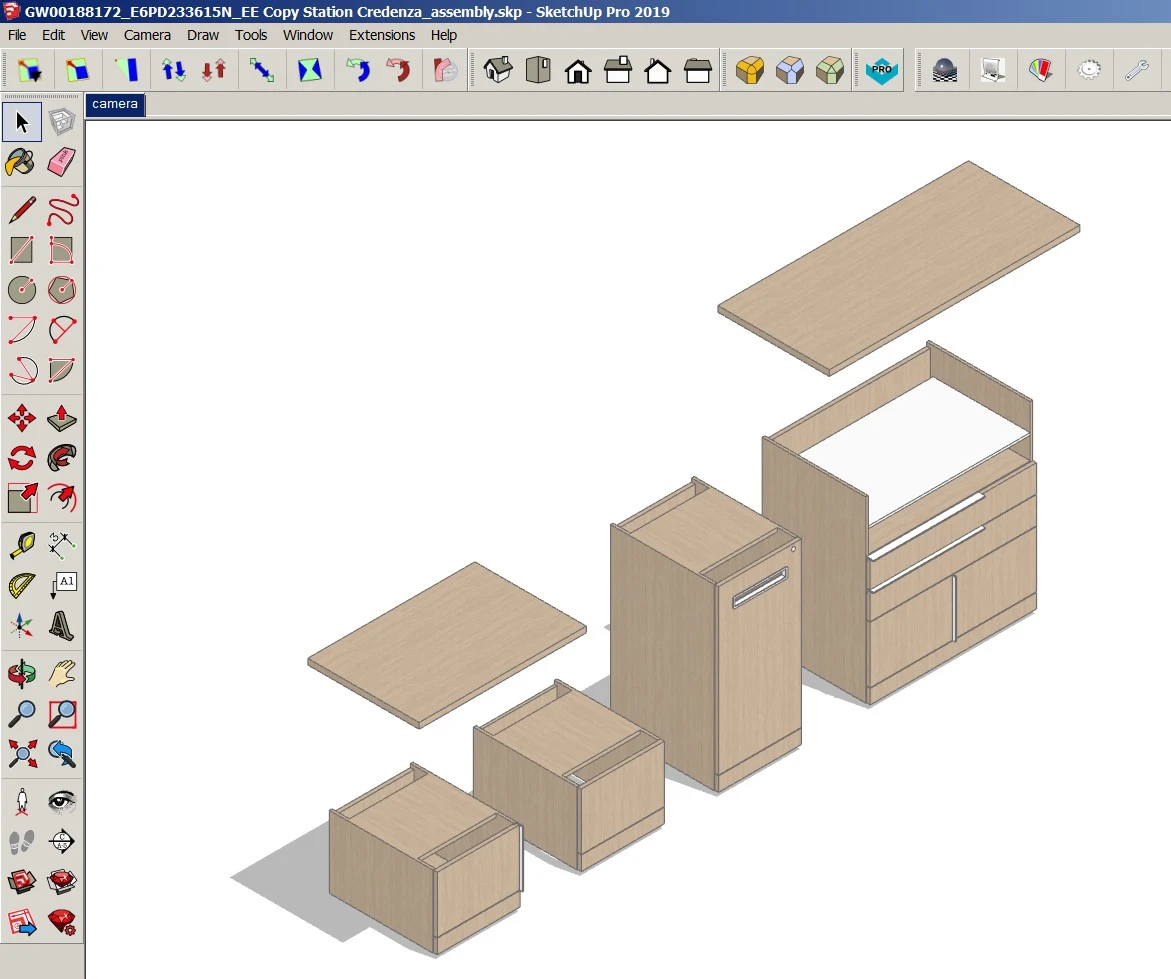

“We would save our CAD models to SketchUp and upload them to 3D Warehouse for users to download,” says Kanoza. “Today, there are thousands of downloads of these models. The 3D Warehouse was a precursor to how we now host SketchUp symbols on Steelcase.com.”

A symbol is a term used for a 3D model that represents a product. When a symbol is accessed from Steelcase’s planning software, it has data connected with information like colors, finishes, materials, and cost reports. This information is all packaged up into the planning software which helps dealer designers organize them into floor plans. Without these symbols, it would be difficult to plan office configurations with Steelcase products.

A SketchUp workflow

New technology meant new workflows and processes with the help of SketchUp. These processes impacted the specials product development process and conceptual design. These new processes require designers, engineers, sales, and quote representatives to work together on product designs – which makes the need for collaboration even more important.

“We use SketchUp in this process. We use it as a composition tool, importing various CAD model types, and adding to them to create visual communication, ” says Kanoza, as he explains the benefits of SketchUp at their company.

Here are two functions that thrive off of the use of SketchUp in particular:

Design validation and application studies. This function helps clients and furniture dealers visualize what a new (special) product will look like when it’s manufactured. To help with visualization, they use 3D models of a special product and place them into the floor plan. This design validation and study establishes the clients’ needs before requesting a mock-up or prototype of the product.

Special design visual communication. This is a new department started by Kanoza, and where he sees the true value of SketchUp. Within this department, the team develops the special symbols of custom furniture pieces.

“We use SketchUp because we need a way to visually communicate the clients’ request for a special-designed product. The special symbol represents a design that has been reviewed by an engineering and quote representative. They conclude if Steelcase can design and manufacture [custom pieces] before we actually manufacture them,” says Kanoza. “If we can show dealers how a product will look, we can get them on board and agree to purchase it before we expend any engineering effort.”

This department’s ability to quickly conceptualize specials is critical to responding to their customers’ special furniture needs.

“Even if we do not win the opportunity to sell a special, we save these drawings on a hosted website for dealers to use for future projects,” says Kanoza. “This is a powerful reuse of the effort. We’ve already validated these designs with engineering.”

Since they have already gone through a rigorous process with all of their designs, they know – in the future – they can quote them fast with the assurance that they can be manufactured. SketchUp is key to the success of this new department.

“It is a cost-effective, efficient way to develop special product imagery,” Kanoza exclaims. “With the efficiencies provided using SketchUp and LayOut, we have developed over 10,000 models of previously quoted product designs.”

They also get a little help from some top extensions: Cleanup3 and FredoScale.

Sharing SketchUp knowledge around the globe

The use of SketchUp at Steelcase is not just limited to the United States. They use it across the globe at other business centers. Kanoza even hosts a global meeting where each region of the world shares SketchUp best practices.

“The benefits I see are the interoperability of the platform, ease of use, and a fast learning curve. It allows all of our departments to collaborate on special product design quotes, fast and effectively.”

Learn more about Steelcase.

Sources:

https://www.steelcase.com/research/articles/topics/employee-engagement/real-work/