We chat with Alan Todd (AIA, LEED BD+C), Senior Virtual Design and Construction (VDC) Manager at Barton Malow Company, which is consistently ranked among the top construction firms in the United States.

Barton Malow delivers new construction, renovation and expansion projects, specializing in markets such as healthcare, sports and entertainment, industrial and higher education facilities. “For nearly a century, Barton Malow Company has been committed to its core purpose of Building with the American Spirit: People, Projects, and Communities,” says Alan. He continues, “As a 100% employee-owned company, this North American contractor features more than 2,000 team members and 14 offices. Barton Malow heads toward its next century of success with the goal of reimagining the construction industry through innovation.”

Let’s dive in to learn more about how 3D is helping them achieve this.

Tell us a bit about how you got into design

Growing up, I really enjoyed the design field. When I was a teenager, I took classes in 2D CAD, started to teach myself to use 3D CAD, and self-learned SketchUp at college.

I got my undergraduate degree in Interior Design, but when I discovered that I’m red-green color blind I realized that my career path wasn’t going to pan out for me. I have memories of being in elementary school, looking at eye color charts and thinking, “I can’t see those dots or those numbers,” but never said anything to anyone.

While studying, I interned for an interior design firm in Richmond, VA where I was doing a lot of 2D CAD work. One of the project managers suggested I look into graduate school for architecture, which is something he always wished he’d done. I hadn’t considered that as an option until that point, but it’s the direction I eventually went in. I also interned for Baskervill, an architecture, interior design, and engineering firm in Richmond, VA before moving on to graduate school, where I got my degree in architecture.

After graduate school, I started my career at FOX Architects and transitioned over to OTJ Architects after a few years. Both firms did primarily interior design, but I was positioned in the Base Building Architectural group of each firm. This was between 2007-2011 when the economy was not doing so well, so I was able to float around departments gathering valuable insights when we weren’t very busy. Being located in the Washington, D.C. area was also a blessing because the federal government, associations, and other legal organizations continued to upsize and downsize throughout the economic downturn. This meant we always had projects to work on.

When I fully transitioned my career from practicing architecture to focusing on BIM and related technologies, I landed a permanent role back at Baskervill as a BIM Manager. This provided a huge opportunity to focus on developing tools and processes around various 3D software.

Interiors to architecture and now Senior VDC Manager at Barton Malow. How did you steer your career to this point?

While practicing architecture in D.C., I gravitated towards and fell more in love with the technology and cutting-edge tools in the AEC industry, rather than with the design process itself. To increase my scope, I went on to work for an architect-engineering firm in Richmond, Virginia for another four years, and then joined Barton Malow five years ago on the construction side.

Although I still really appreciate design, I focus a lot of my efforts and energy on understanding how to leverage 3D software tools including virtual and augmented reality apps, laser scanning, and other technologies that have emerged over the past five to ten years.

Interestingly, there was no degree in Virtual Design and Construction (VDC), but everything I’ve learned and experienced has served me in my current role. In addition to being software savvy, I found that being able to work well with a wide range of individuals who are sometimes technology averse, is a critical skill. This is simply because a large part of VDC is customer service. Our teams understand the value of learning a new skill that keeps our projects safer and running more effectively.

What does Virtual Design and Construction mean to Barton Malow?

VDC tools and processes enable us to be better builders and partners. Through technology, we enhance communication, collaboration, and transparency with all project stakeholders. Our tools, whether digital or analog, allow for process-driven decisions that honor our commitments and deliver project value.

The Barton Malow VDC team supports project types that vary greatly in size and complexity. We work hand-in-hand with individual members of our project teams to build a VDC-enabled workforce. Connecting and partnering subject matter experts with job site personnel decentralizes expertise from the office to the field, where it matters most. However, we typically don’t use the same tools on every project. We are strategic about which technologies we deploy and deliver based on site conditions, teaming arrangements, scope, and other factors. This ensures we are using the best tools to overcome unique project challenges and ultimately bring tailored value to owners.

How does 3D modeling factor into your typical workflow?

We use SketchUp primarily as a communication tool with our clients and user groups in service-oriented market sectors such as healthcare, higher education, and sports. All project stakeholders need to understand the construction logistics and sequencing strategy so we can develop effective safety plans, maintain access for existing/neighboring occupants, and know how the project will be built. Additionally, the 3D environment is great for understanding how the new building or space will look, function, and feel when the project is complete. We find that some of our stakeholders are unfamiliar with reading 2D plans and some non-AEC viewers are intimidated when opening 3D models in a drawing environment. To counter this, we work with architects and designers to develop 3D representations of our projects and create 3D PDFs from virtual mockups. We’ll export the 3D PDFs as U3D files (a file format that is used to embed 3D interactive data and models into a PDF file) or other easily accessible formats.

Additionally, the 3D environment is great for understanding how the new building or space will look, function, and feel when the project is complete.

Working in 3D also transforms the process of collaboration with the wider project team, creating a partnership environment across architects and engineers. It helps us bridge the gap, communicate our construction strategy, and collaborate in a format that’s familiar across all stakeholders.

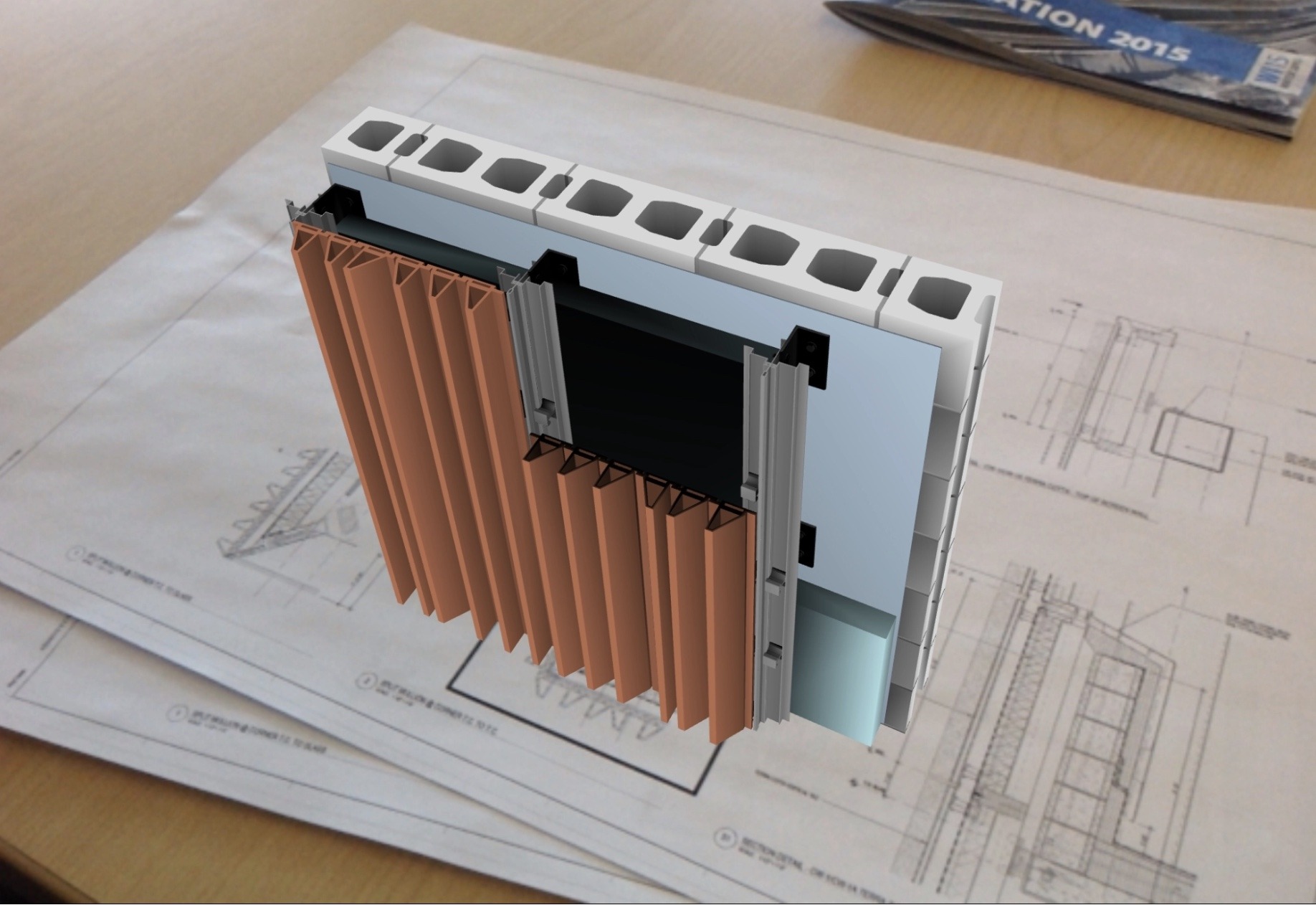

VDC and 3D technology facilitate early decision-making. In some cases, we’ll create a virtual reality environment to review sophisticated details such as curtain walls that are intricate and require careful sequencing to install, instead of building a physical model which adds cost, time, and material waste.

These 3D details and animations help our trades better understand the build process, logistics, and safety concerns.

How does SketchUp help you compete in bids and deliver at the construction site?

In our workflow, we use SketchUp and other tools within the Autodesk and Naviswork suites. For 3D logistics visualizations, we generate SketchUp models of individual site components, such as cranes, trailers, plant equipment, and street traffic. We’ll bring these components into Enscape or Lumion to enhance the visual quality and paint a clear picture of our phasing approach or sequencing strategy. We also develop virtual reality experiences with IrisVR to quickly generate virtual mockups that drive early decision making. SketchUp fits in nicely in the early stages and is instrumental when the schedule changes over the course of the project and we need to quickly update logistics visualizations.

In unique scenarios, where the customer envisions a SketchUp-like deliverable at the end of the project, we will use it throughout.

What are your most-used extensions?

We use CleanUp3 for tidying up models, Selection Toys for more refined selections, and FredoTools for modeling curved surfaces. We work with Key Frame Animator to animate logistics sequences, which allows us to present details such as vehicle and crane positioning. These tools are essential in our VDC workflow and help to communicate a story.

What sets Barton Malow apart from other construction firms?

For me, it’s the firm culture. Barton Malow is a large company which was a concern for me when I joined because I thought I might just be a number, but being family-owned and run, that’s not the case. We’re structured in such a way that team members have exposure to a large number of people across the country. The culture is one of a big family made up of good people who are working to help each other achieve the same goals. Our processes and tools are greatly integrated so there’s a lot of consistency across the organization.

Our president and CEO, Ryan Maibach, has a keen business sense and a passion for technology. He understands that there are tools that can drive efficiency, increase on-site safety and collaboration, and reduce waste. He encourages the entire team to constantly think, unlearn and relearn.