Turner Construction Company is a global construction and building services company with a 10,000-person strong team, completing 1,500 projects annually with a value of $13 billion. The North America-based company has built a reputation for delivering large, complex projects using innovative and emerging technologies. These projects are made buildable by regional Virtual Design and Construction (VDC) teams. One such department is led by Renzo di Furia who applies his fifteen-year construction model building experience as Northwest Regional VDC Manager.

Renzo’s group develops operational process improvements through applied research, specializing in parametric modeling, and digital prefabrication. Follow along as we discuss how the team leverages technology and research to deliver high-impact projects.

Renzo, tell us a bit about yourself and how you started 3D modeling.

I started my career working as a carpenter while simultaneously attending college for a Construction Management degree at the University of Washington. After graduating, I worked as a project engineer for a large commercial contractor in Seattle for about five years. At that time, there was a regional need for more project superintendents (an on-site project manager that ensures project quality and success) so I transitioned and served in that capacity for fifteen years, working on many high-profile projects.

I joined Turner as a concrete superintendent in 1999 when our Seattle office first began to self-perform concrete. To self-perform concrete means a company delivers the concrete work on a project without relying on external contractors.

When my twins were born in 2003, stable hours and weekends with my family became more important; so, I transitioned into estimating and ended up, to my surprise, enjoying it!

Soon after, I was offered a company-sponsored opportunity to learn and implement a model-based estimating workflow. I had taken SolidWorks classes a couple of years before at a community college and had also built physical models, but the time and money required for the latter had prevented implementation across the company’s projects. The idea of virtual modeling from the superintendent and estimating perspective was too good to pass up.

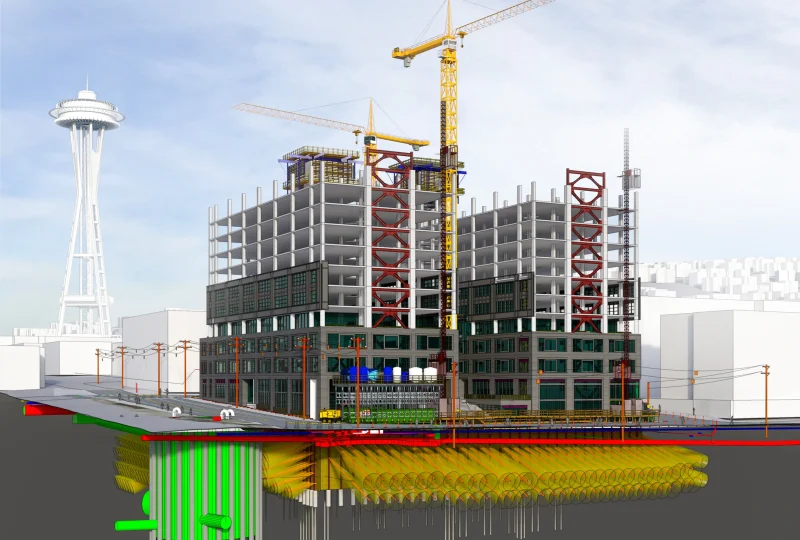

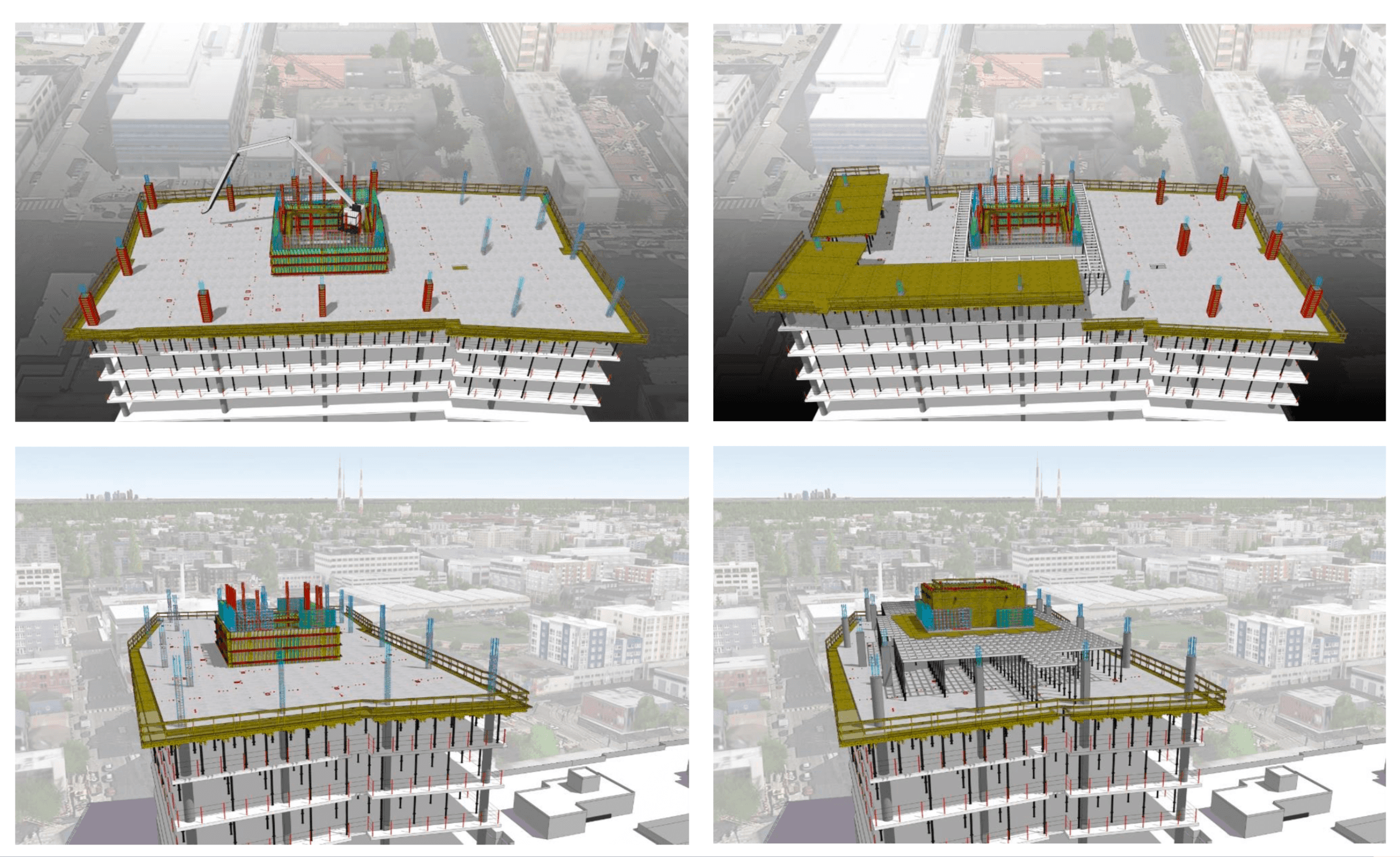

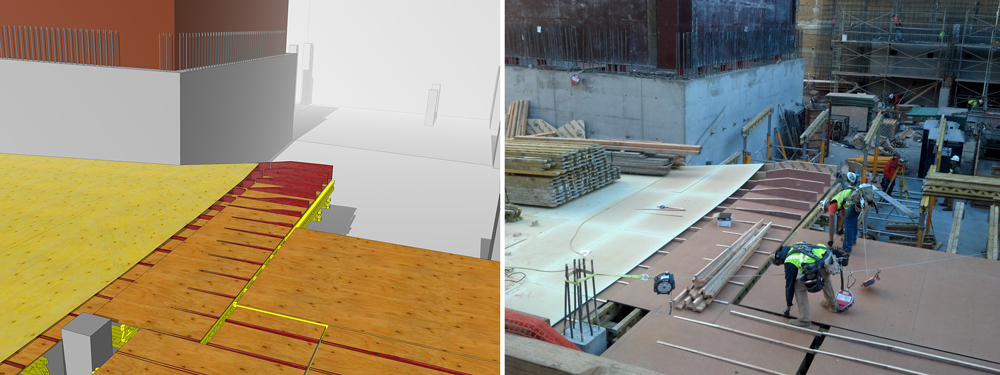

Following the training, I started our model-based estimating program in 2006, which focused on supporting the company’s self-perform concrete operations. That first success led to subsequent model-based implementations which have now become the foundation of my VDC department. We design and implement concrete formwork and rebar, produce lift drawings, plan site layout for efficient logistics and safety, and deliver wood framing, miscellaneous steel shops, and laser scanning. We also have a scale model building shop with 3D printers and an industrial CNC router that we use for concrete formwork prefabrication.

You now hold a key role at Turner. Tell us about it and the team that you manage.

Today, I manage Seattle’s virtual design and construction (VDC) team. We operate as a centralized group, providing all the required expertise from our main office and no longer place VDC engineers on multiple job sites. Over time, we’ve gradually expanded our services to include other Turner business units; and now a third of our work volume is for projects outside of the Seattle business unit.

As a team, we have over 120 years of combined construction experience, with a mix of architects, project engineers, carpenters, construction, and architectural technologists. We range from interns to seasoned practitioners, fresh graduates to folks with master’s degrees, and PhDs. Overall, it’s a highly educated group with technology and operational backgrounds.

What are some of your typical projects?

Turner delivers preconstruction, demolition, construction, redevelopment, seismic reinforcement, infrastructure repair, and renovation services on projects ranging from schools to stadiums, residential to commercial, multi-story office complexes, mixed-use developments, aviation, transportation, healthcare, and infrastructure.

Some exciting Turner projects include the Seattle Aquarium, which is currently in preconstruction, and a 50,000-square-foot pavilion adjacent to it with a 325,000-gallon warm-water tank that will house sharks, rays, and other larger species.

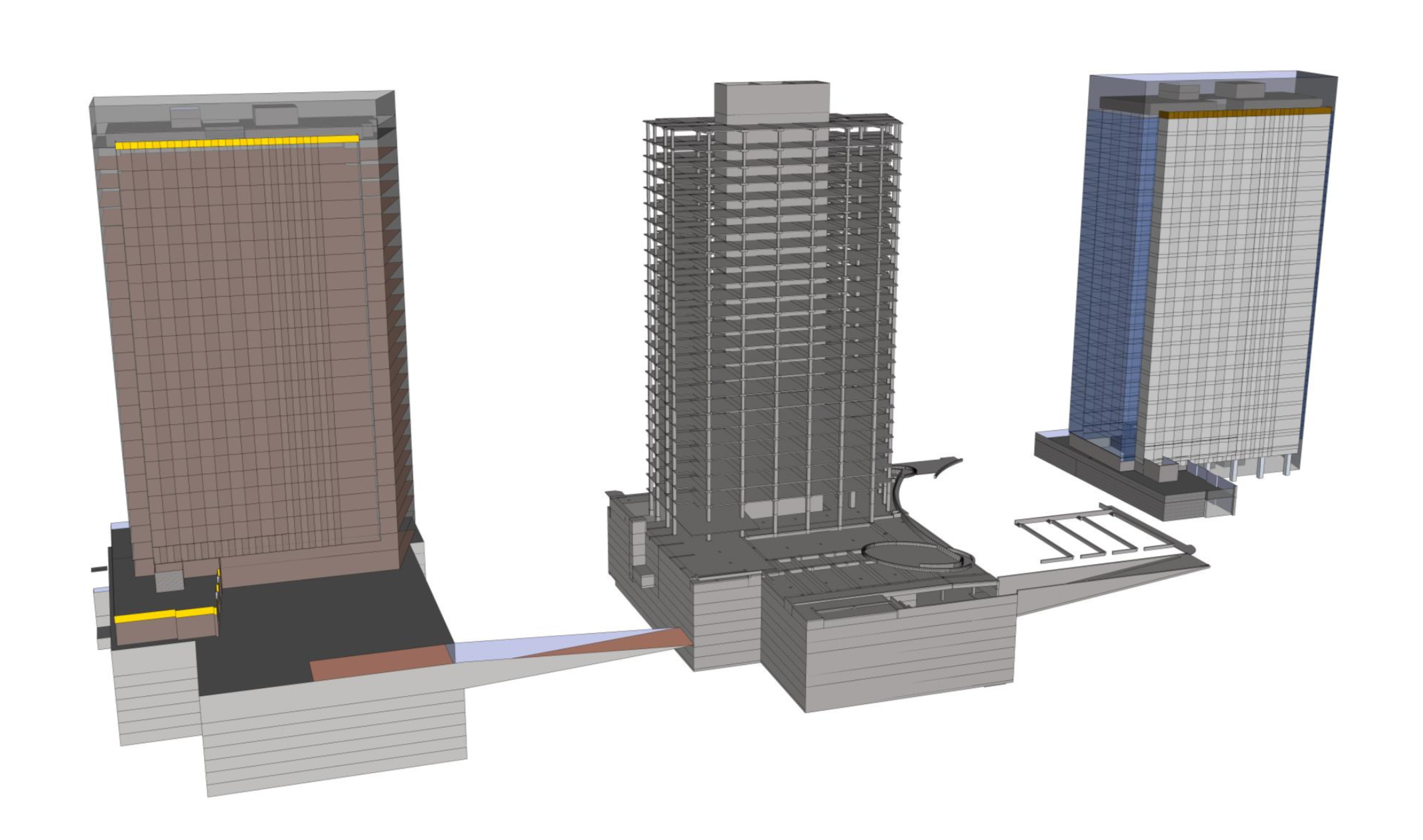

Another iconic project for Turner that is currently under construction is the 42-story tower located at 555 108th. Set to be the tallest in the Seattle suburb of Bellevue, it has approximately one million square feet of rentable space (approximately 1.5M square feet with parking). The concrete core and steel superstructure tower includes a pavilion, a public plaza, a retail pavilion at street level, and five levels of below-grade parking.

How do you start a new project?

Most of our projects start at the pre-construction stage, typically with a guaranteed maximum price cost-contract. With this contract type, the client is assured that the project will not exceed a certain price, regardless of changeable factors like material costs or economic fluctuations. As opposed to bids, we negotiate contracts with owners who are often returning customers. As such, we are usually engaged during pre-construction to help develop and complete the design, a process that sometimes takes more than a year before site work begins.

In addition to this, we support our business development department with generating bids by creating visual content that tells a clear story of how we plan to build the project. This could take the form of 3D printed or laser-cut timber models produced in our onsite model shop. When the project is awarded, the next step is estimating.

For the purpose of estimating, we always build our own 3D models with a quality control model in SketchUp to map out the desired square footage, surface area, and volume. Next, we build a detailed concrete model in ArchiCAD, laid out with the self-perform process in mind. Finally, we create an exterior envelope model in SketchUp specifically for quantity takeoff.

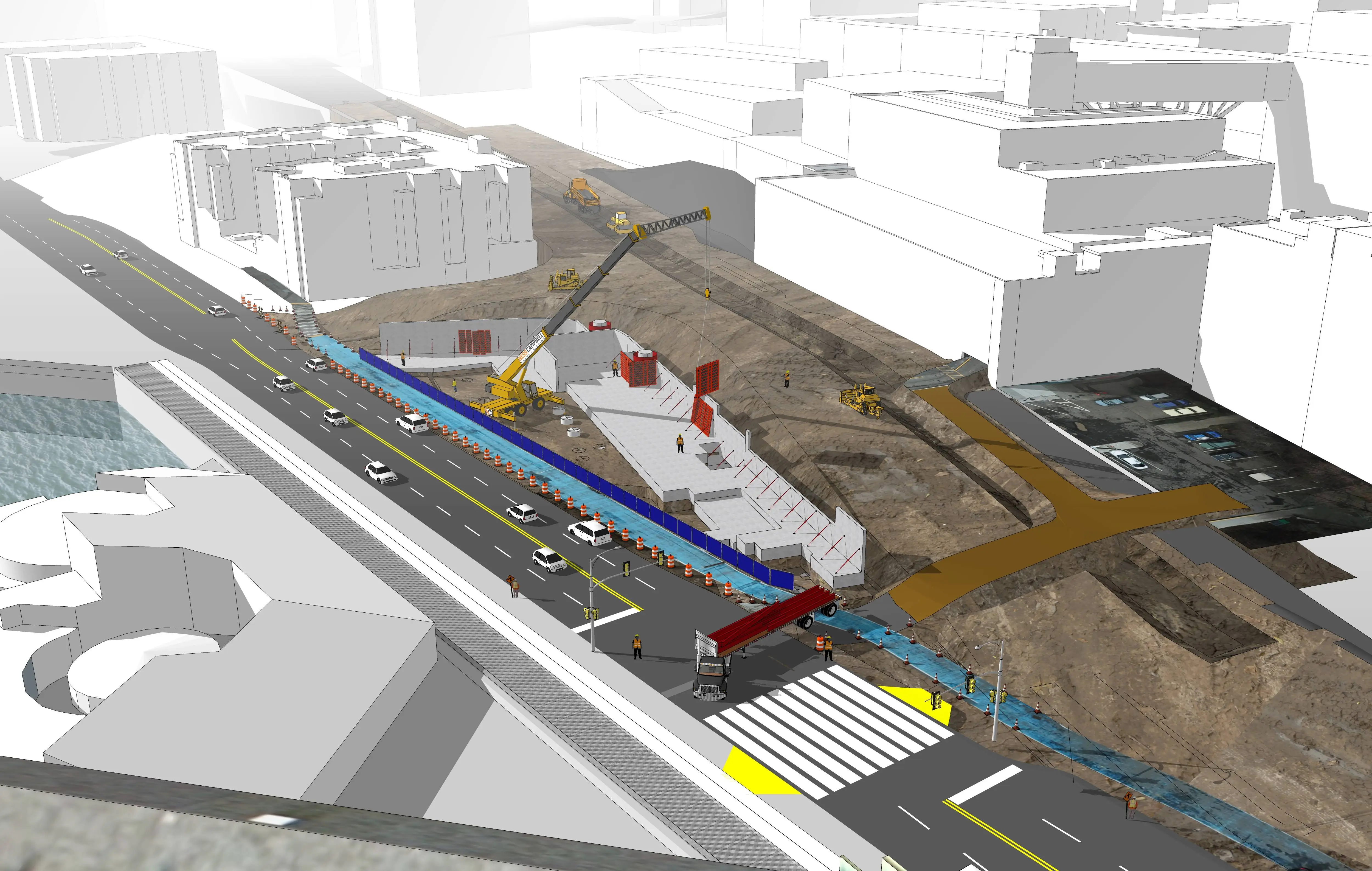

Beyond this, we explore logistics planning in 3D by using SketchUp to develop the construction sequence and other detailed drawings. 2D logistics plans were and still are being used today by many practitioners.

Instead of simply listing data, we aim to tell a rich, multi-dimensional story and immerse the client in our solution.

SketchUp equips us to develop and tell a much better visual storytelling in 3D. It also ensures that designers put more thought into proposing impactful solutions.

What has technology added to Turner’s process efficiency?

We have always focused on refining our process over accruing technology, particularly when exploring new opportunities to use construction tolerance modeling to improve existing workflows. For us to achieve repeatable, predictable, and scalable implementation, we’ve realized that improvements need to be familiar, easy to understand, and compatible with existing practices. By adopting a scientific approach where practice and measured results are more important than a hypothesis, we’ve been able to avoid unintended negative consequences.

Although we use many 3D software programs, our workflow utilizes SketchUp for more than 50% of all-out modeling tasks.

The ability SketchUp gives us to pre-plan in great detail using construction tolerance modeling has helped us to eliminate waste while increasing production, quality, safety, and customer satisfaction.

What other Trimble products contribute to your workflow?

Our tech stack is extensive and includes both Trimble software and hardware. We recently purchased a TX8 Scanner for laser scanning, and use Trimble RealWorks for point cloud processing and analysis. We rely on Trimble Total Stations for model-based layout.

Trimble’s Tekla is the go-to for all our rebar and concrete lift drawing modeling. It enables us to carry out detailed constructability planning for complex installation sequences, a process that isn’t always pre-planned in the industry.

Doing this cuts out a lot of waste and errors, and helps us bake in extensive efficiency into our build process.

An added benefit of rebar modeling is that we can divide building components into truck delivery loads. This helps us keep tight control on just-in-time site deliveries and improves project efficiency.

Another benefit of the holistic Trimble solution is that we can seamlessly export our Tekla rebar models into SketchUp to pre-plan the erection of the map footings, which makes our design solutions more accessible to non-specialists. We organize the SketchUp model into layers, leverage scenes and textures to differentiate between build stages, and collaborate with material manufacturers to determine exactly how things will be built and bundled for delivery.

From your observations, how has technology transformed the construction industry over the past few decades?

The adoption of new technologies has had a profound effect on eliminating waste and increasing productivity, but it can also lead to unexpected negative consequences. The proliferation and evolution of technology has led to an exponential increase in the amount of gathered and generated data. The industry now requires a more technically skilled staff in order to manage and interpret this data as previously simple tasks have become more complex. That being said, we are able to envision, design, and construct buildings that would have been unimaginable thirty or forty years ago.

What are some future trends you foresee within the industry? Can technology unlock greater growth within the construction industry?

Digital prefabrication and the use of construction robotics are two areas that will see considerable growth and adoption. These technologies rely heavily on sophisticated model building and model coordination skills, so I’m excited to see where that will lead. I’m confident that we will create improved working environments and reclaim lost craftsmanship. In order to ensure success, the industry will need to do a better job providing attractive career opportunities for young professionals interested in technology and construction.

About Turner

Turner Construction Company was founded in 1902 by Henry C. Turner and pioneered the use of steel-reinforced concrete during the turn of the century to create safer, stronger, and more efficient buildings. Today, Turner has an approach to innovation that channels the ingenuity of its people to advance breakthroughs and deliver new value to clients and partners. Turner Construction’s Corporate offices are located in New York City.